Summary

- A PTFE pipe caused frequent filament jams.

- Multiple prints led to consistent printer jams in the same part of the process.

- Upgrading to Unicorn Trimetal Hotend solved all issues.

By and large, my Creality K1 Max printer has been a great workhorse, and I’ve literally printed hundreds of pieces for personal use and to be sold at market. However, there was one annoying problem, and after many months Creality has essentially solved it.

My 3D Printer Had a Glaring Flaw

When I reviewed my K1 Max I basically put it through just over a week of absolute torture out of the box, and it performed much better than I had ever experienced with any 3D printer. However, after a few months of use, I would always run into jams that required opening up the print head, sometimes even into the extruder gears, and cleaning out a jam.

Whenever this happened, a common denominator was this little PTFE (I assume) pipe that leads from the extruder into the heat break.

What would happen is that the filament would get stuck solid in this pipe, which meant having to run hot water over it to clear the jam. Eventually, I could do this in five minutes with my eyes closed, but running into this jam some mornings when I had an order to fill from an overnight print was a big bummer.

Some Models Just Wouldn’t Print at All

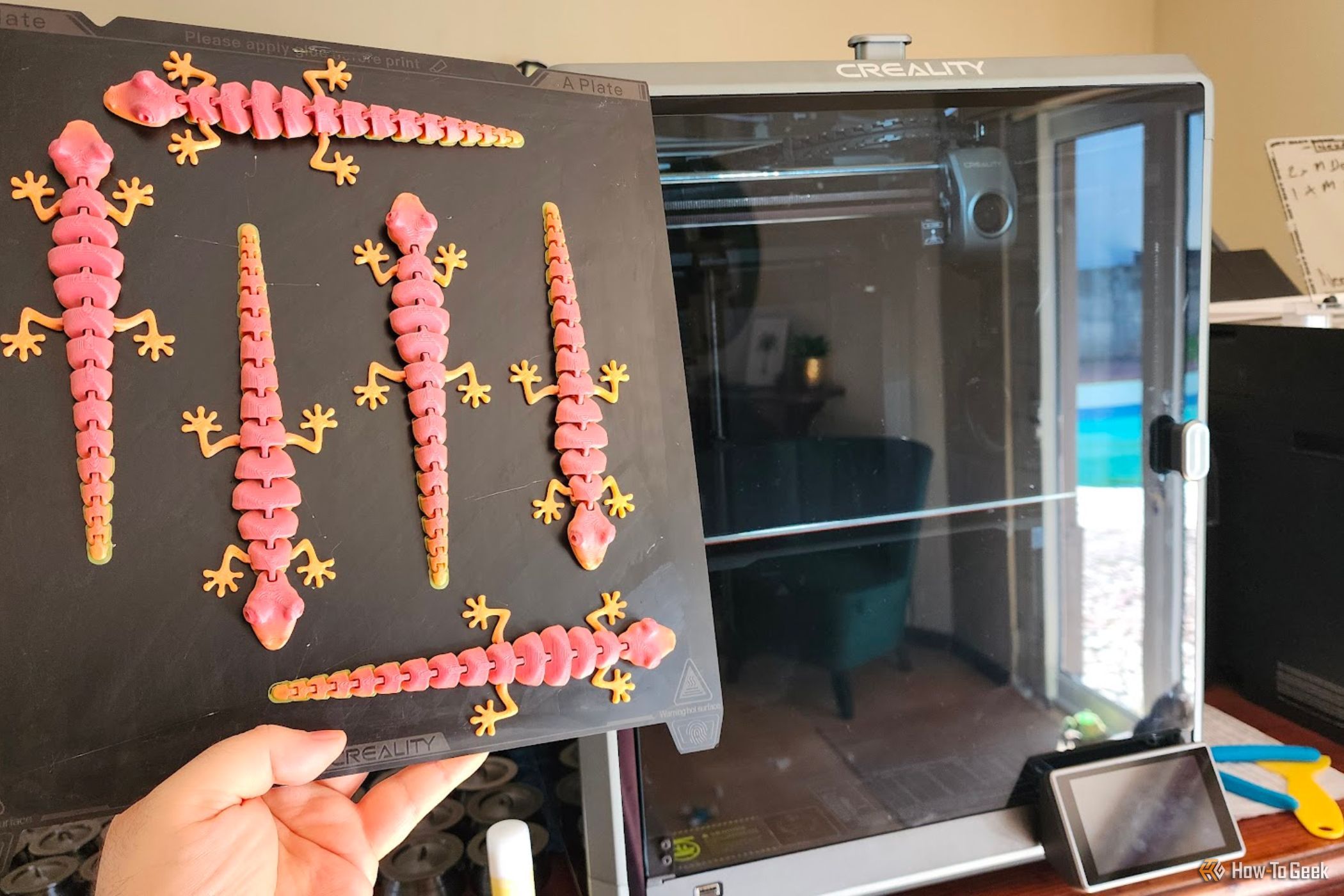

I did a lot of troubleshooting over the months with this issue, and it seemed most likely to happen when I had multiple copies of models on the plate. Which is why I got the K1 Max in the first place—to use all that space! Whenever the print head hops from one model to the next, it has to retract the filament to prevent dribbles, and this back-and-forth grind would cause filament to get stuck in the pipe. Since that little pipe gets no heat, you can’t rely on the filament to remain fluid and moving.

Some of my models were impossible to print, and would always jam the printer in the same place, which meant having to modify or abandon those prints until I could find a solution.

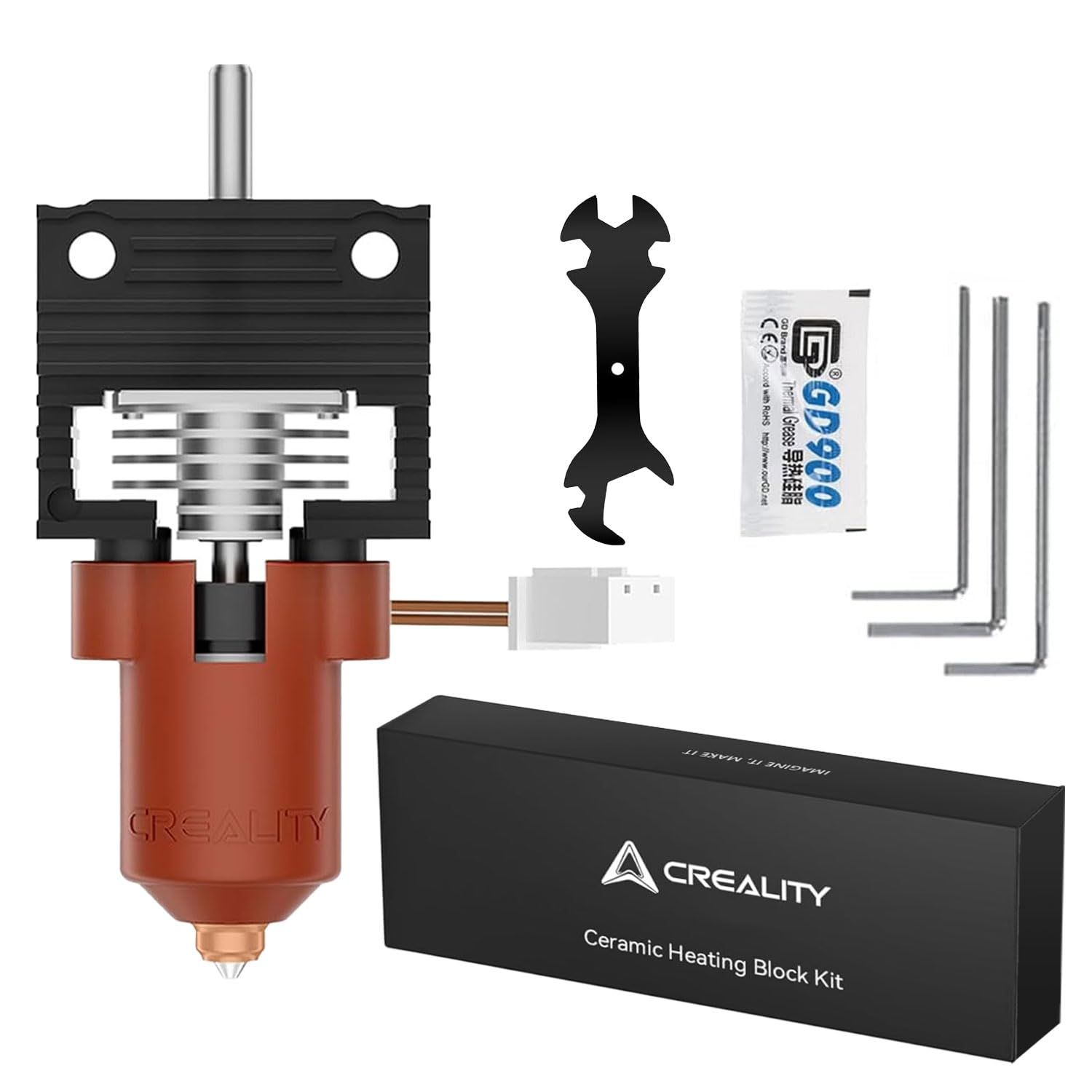

I’d been reading about these jams and banging my head against the wall for some time, and then I saw the Creality K1C. This is a version of the K1 meant to print carbon fiber filament, and it has a trimetal hotend that doesn’t use the little plastic pipe, but metal all the way through from the extruder to the nozzle.

So I sent my K1 Max in for a much-needed service, and asked them to upgrade it using the new hotend kit. After a few days, my now-shiny printer returned, and I was holding thumbs this design flaw had been rectified.

Everything Prints Perfectly Now

Spoiler alert—it worked! Everything that had failed before now prints fine. I can put as many copies of a model on the plate as I like, and queue 30+ hour prints without worrying that I’ll wake up to a printer that’s trying to build on thin air.

Honestly, Creality should probably have used an all-metal design from the outset, but I can absolutely see how this would never be a problem for a hobbyist who only prints relatively low volumes. Not someone who has to make 100+ articulated dragons each month.

If you’re looking at getting a Creality K-series printer that doesn’t yet have this upgrade, I strongly recommend getting it done as soon as possible. There are other benefits to having this new head as well, including a hardened tip to handle more abrasive filaments, and better heating and flow in general.

I have definitely noticed an improvement in quality. My prints have less stuff to clean, and there have been no downsides that I can see.